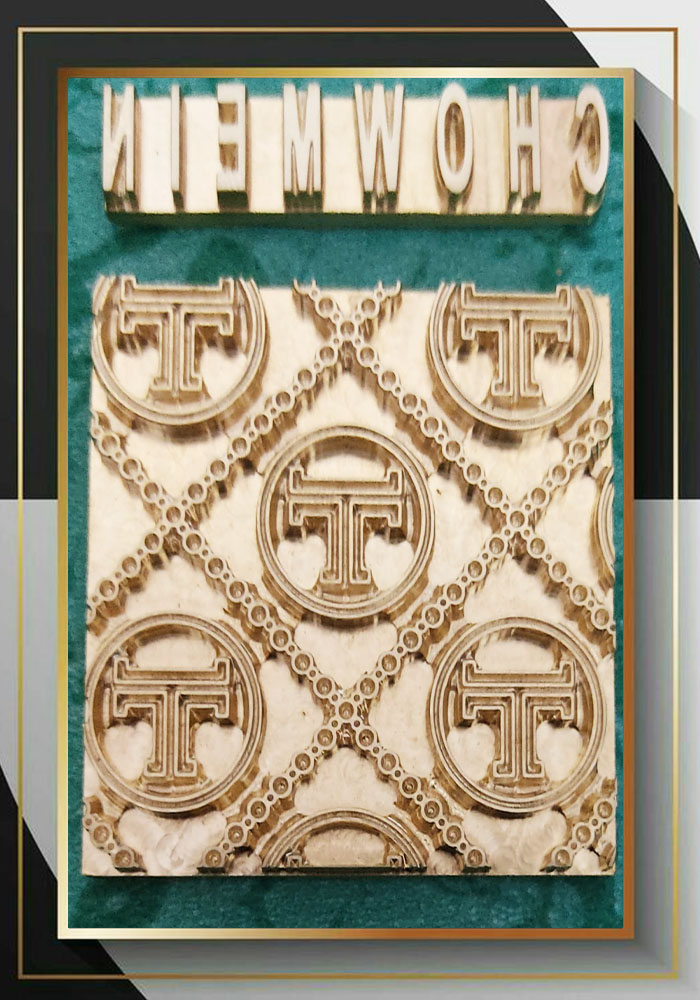

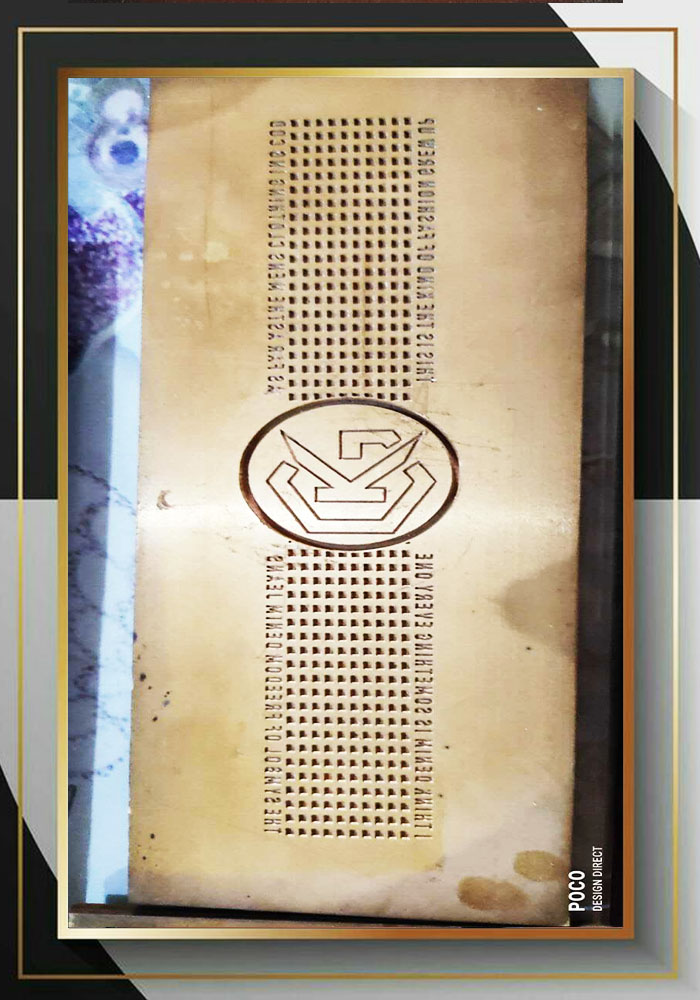

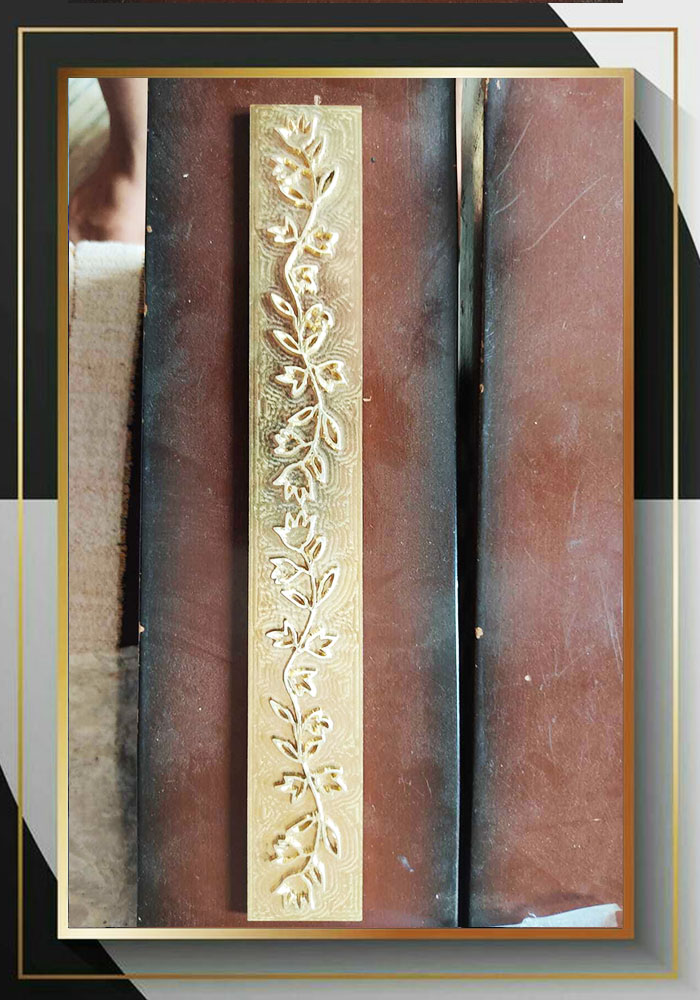

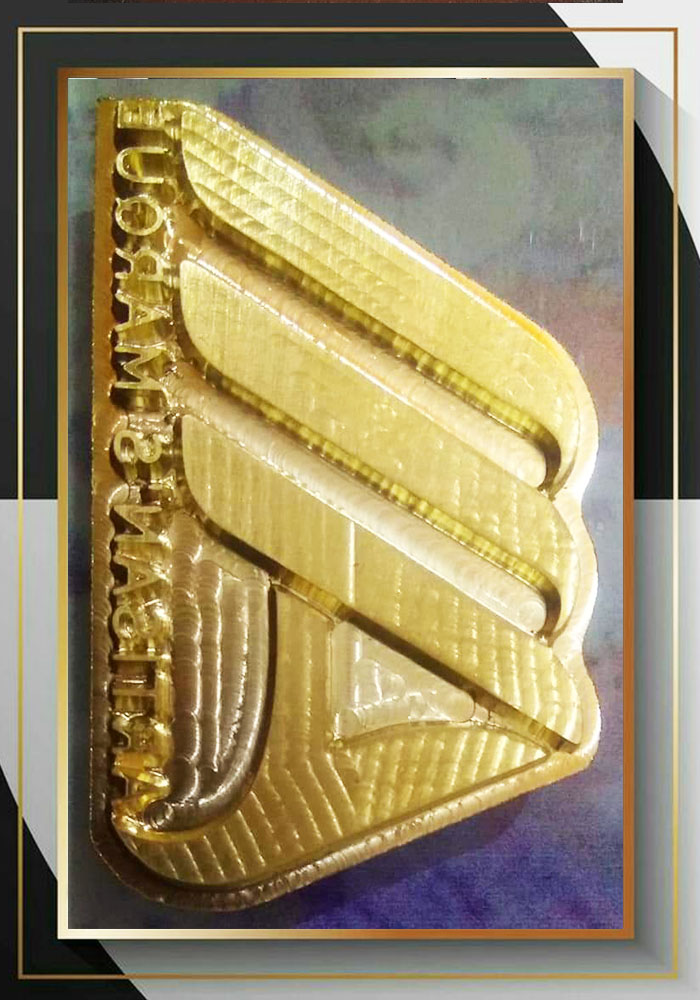

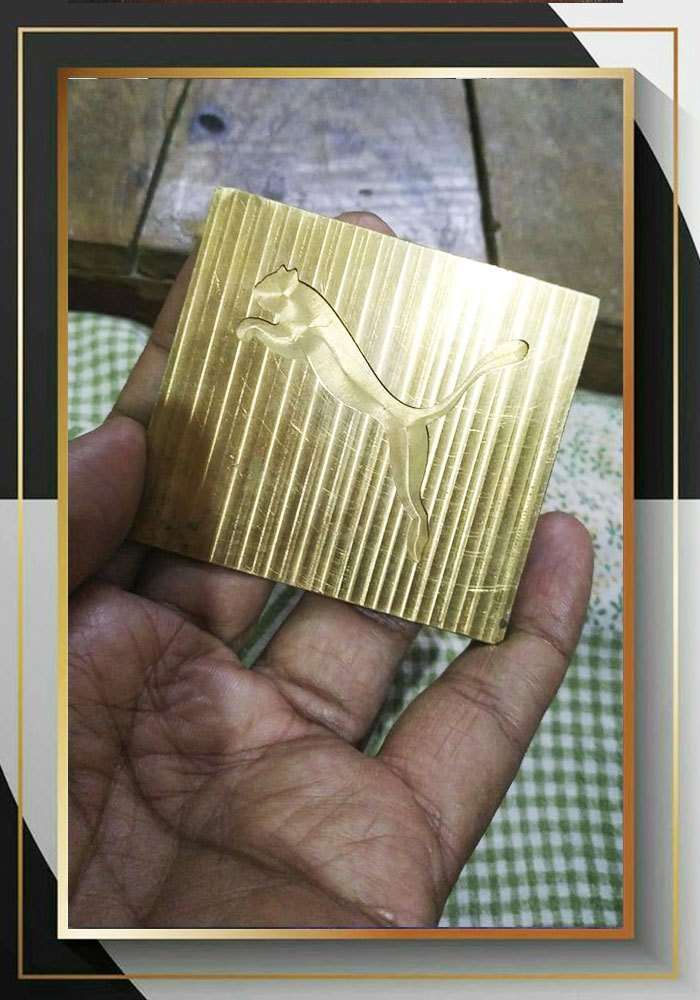

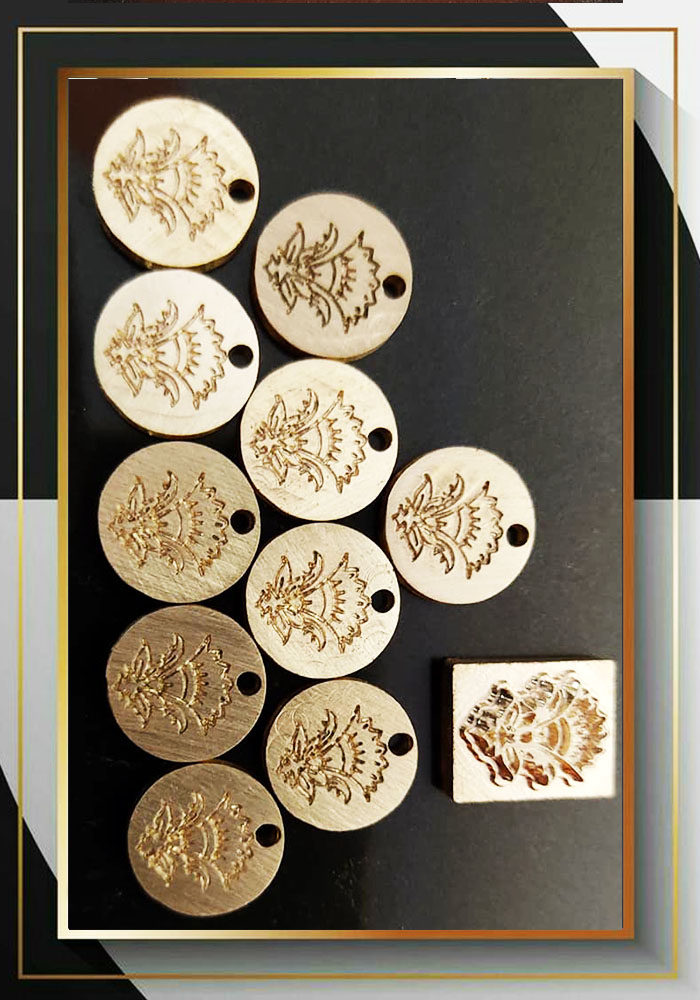

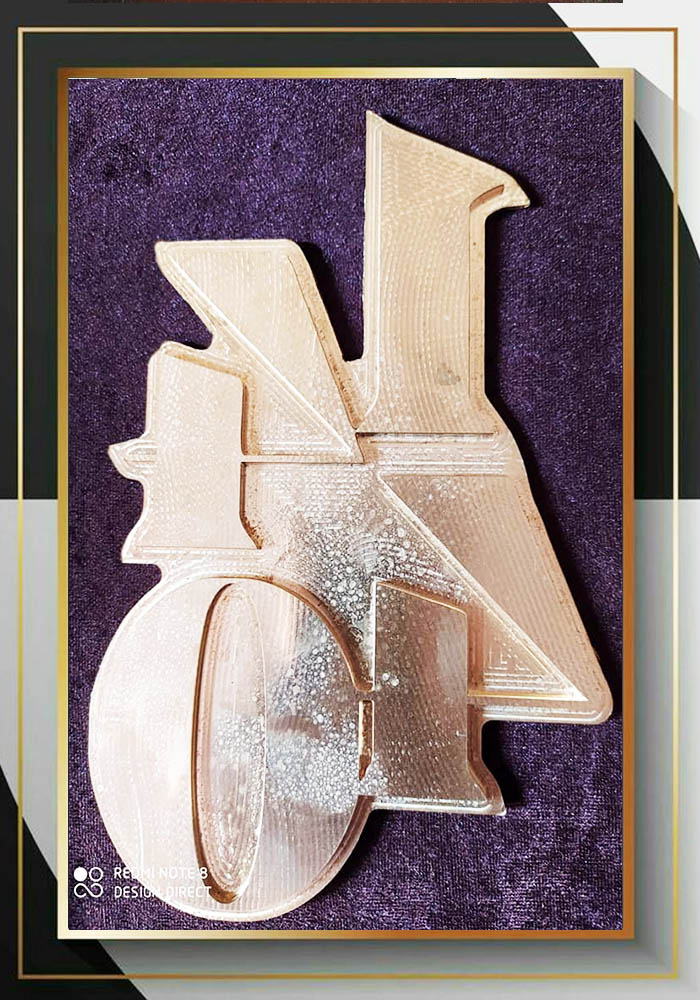

Brass Embossing Die Manufacturer

In the commercial and residential door hardware industry, brass stands out for its durability, although it requires protection from prolonged exposure to outdoor conditions and abrasion. It finds extensive use in applications where low friction and spark resistance are critical, such as in electrical components, heavy artillery, and ammunition casings. The brass stamping process, also referred to as brass pressing, involves shaping a flat brass sheet using specialized stamping presses. Techniques like punching, coining, embossing, bending, blanking, and flanging are employed to create a variety of intricate forms and components. For brass embossing die manufacturing in Delhi, Design Direct India offers specialized expertise and advanced technology. They excel in crafting precision brass embossing dies that meet the stringent requirements of diverse industries.

Techniques in Brass Stamping

- Progressive Die Stamping:- This method divides production into stations, ensuring precise shaping of the brass strip as it progresses through each station. It guarantees accuracy in the final components used across diverse industries.

- Transfer Die Stamping:- Utilizing a mechanical transport system, this method efficiently produces parts needing complex features like cut-outs and threading. It's cost-effective and adaptable across sectors such as agriculture, transportation, and electronics.

- Fine Blanking:- Ideal for creating components requiring flatness and a clean edge, fine blanking utilizes cold extrusion in a single step, reducing manufacturing costs significantly. It's commonly employed in producing precise components like gears.

- Four-Slide Stamping:- Employing four tools simultaneously, this method efficiently creates complex bends and cuts in metal sheets. It's suitable for applications needing intricate shapes with minimal waste.

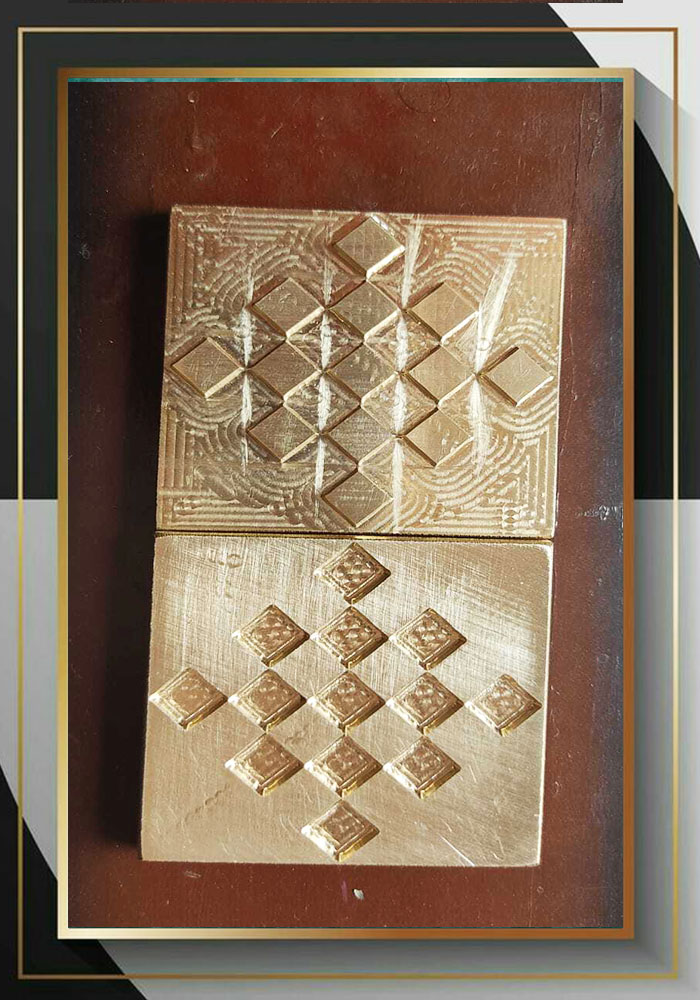

Best Brass Embossing Materials

When it comes to brass embossing, choosing the right material is crucial. Brass alloys like C260 and C280 are popular choices due to their excellent formability and durability. They offer superior embossing capabilities, making them ideal for applications requiring intricate designs and high aesthetic appeal.

Why Choose Design Direct India as Your Brass Embossing Manufacturer ?

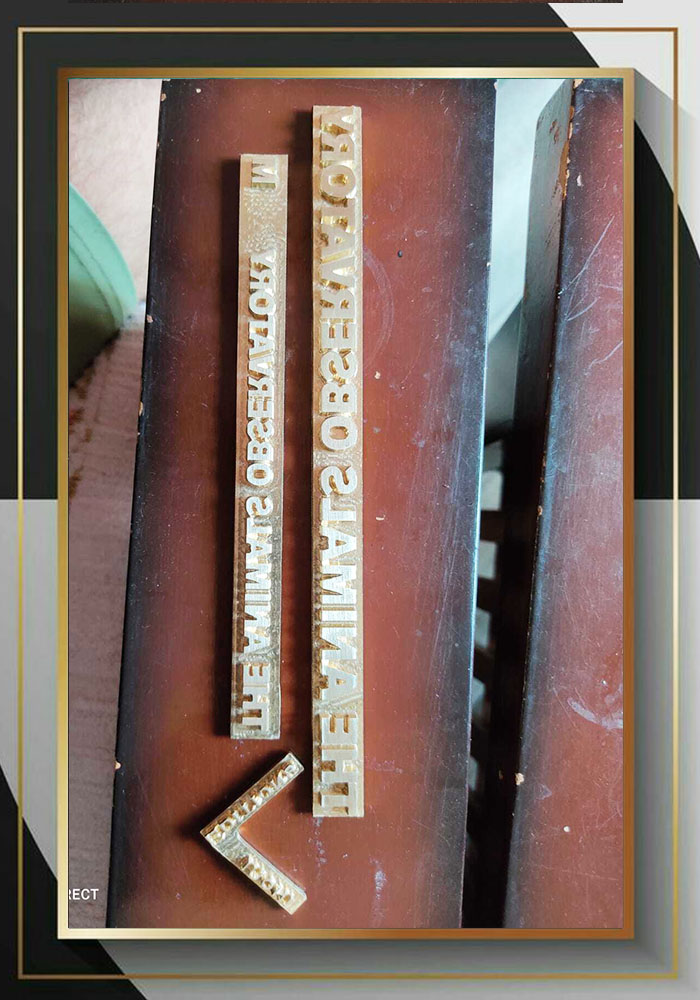

- Expertise and Experience:- With years of experience in the industry, Design Direct India has honed its craft in brass stamping and embossing, delivering high-quality, precision-engineered components.

- Advanced Technology:- Utilizing state of the art stamping presses and CAD software, Design Direct India ensures superior accuracy and consistency in every product.

- Custom Solutions:- Tailored to meet specific client requirements, their brass stamping solutions encompass a wide range of applications, from intricate electronic components to robust ammunition casings.

- Cost-Effectiveness:- Offering competitive pricing without compromising on quality, Design Direct India provides cost-effective solutions that meet budgetary constraints. Whether you need brass stampings for industrial machinery, electronic devices, or decorative hardware, Design Direct India's commitment to excellence ensures optimal performance and reliability in every product.

Conclusion:- Choosing the right brass stampings manufacturer is crucial for ensuring the quality and performance of your components. Design Direct India, with its dedication to precision, technological expertise, and cost-effective solutions, stands ready to fulfill your brass embossing needs. Visit their website to explore their capabilities and request a quote tailored to your specific requirements.